Background

2023

Exploration

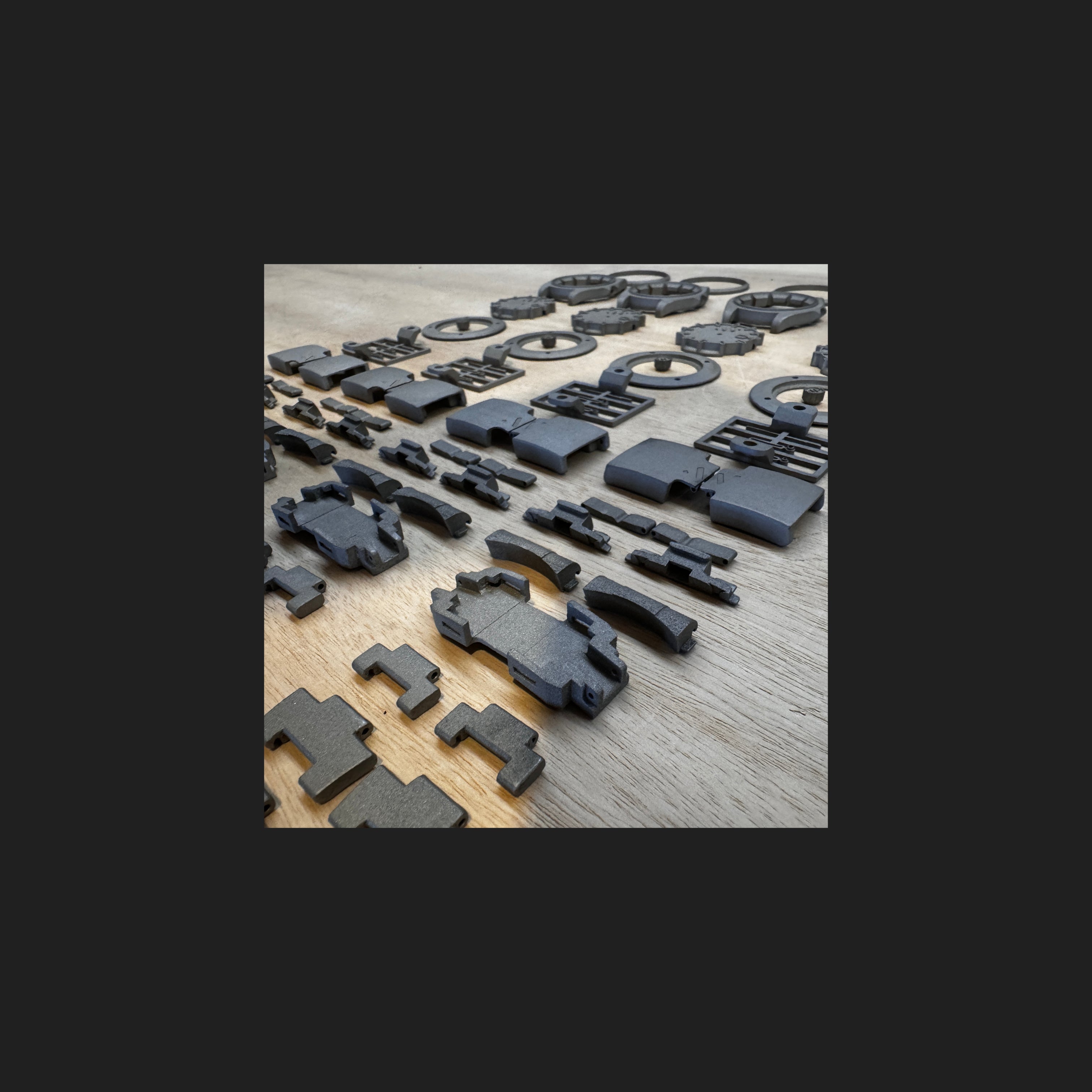

The early 2020s marked a shift for me from digital systems to physical engineering. Leveraging the accessibility of modern prototyping, I began exploring product design and manufacturing workflows. This phase was defined by the study of mechanical movements. By deconstructing existing calibers and experimenting with metal 3D printing, I moved beyond simple curiosity to a systematic analysis of how traditional horological architectures could be improved.

2024

Foundation

With traditional watchmaking school not an option, I went directly to the source material. I approached EPFL Press with a proposal: to translate the 1,200-page industry bible, Traité de Construction Horlogère, into English. Over nine months, this project became a rigorous, self-directed apprenticeship. I didn't just translate the text; I studied the physics and engineering principles behind it. This provided the theoretical bedrock necessary to move from assembling components to engineering them from scratch.

2025

Production

Theory required execution. I established AW Labs to turn theoretical knowledge into physical reality. Transitioning from prototyping to production, I brought the manufacturing process in-house to gain complete creative freedom. The goal was not to replicate the past, but to explore original design concepts and push my own technical limits, launching a brand defined not by heritage, but by engineering integrity.